Microsoft Dynamics 365 Business Central Manufacturing

Streamline Your Shop Floor and Optimize Production with Unified Manufacturing

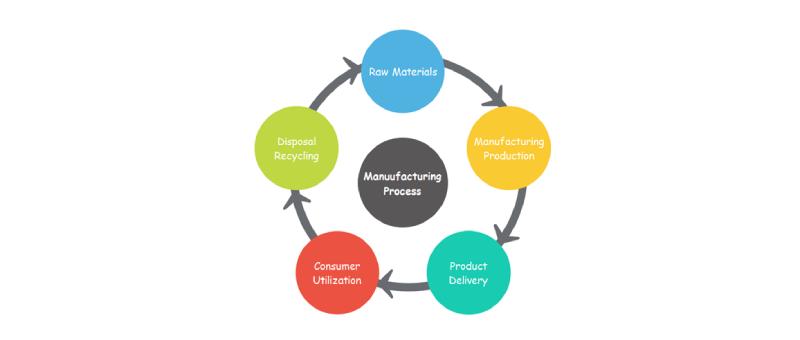

From Raw Material to Finished Good: Master Production, Control Costs, and Scale with Confidence.

Microsoft Dynamics 365 Business Central Manufacturing

Streamline Your Shop Floor and Optimize Production with Unified Manufacturing

From Raw Material to Finished Good: Master Production, Control Costs, and Scale with Confidence.

Microsoft Dynamics 365 Business Central Manufacturing

Streamline Your Shop Floor and Optimize Production with Unified Manufacturing

From Raw Material to Finished Good: Master Production, Control Costs, and Scale with Confidence.

For modern manufacturers, complexity is a constant challenge. Disconnected systems, inaccurate inventory data, and inefficient production schedules lead to wasted materials, missed deadlines, and shrinking margins. To compete, you need real-time visibility and control over your entire production process.

Microsoft Dynamics 365 Business Central delivers a robust, integrated manufacturing solution that connects your shop floor directly to your financials, sales, and supply chain. It provides the tools to master both simple and complex production environments, turning operational data into a competitive advantage.

As a trusted Microsoft Partner, we implement these powerful capabilities to create a seamless and efficient production operation. Here’s how we leverage Business Central’s core manufacturing functionalities to drive your growth:

- Master Planning and Scheduling for Optimal Flow: Automatically generate realistic production plans that synchronize supply with demand. The Master Production Schedule (MPS) and Material Requirements Planning (MRP) engines calculate net requirements, create purchase orders for raw materials, and release production orders, ensuring you have the right components at the right time to meet your production goals.

- Gain Precision with Advanced Production Bill of Materials (BOMs): Define your products with accuracy and flexibility. Manage multi-level Bills of Materials (BOMs), including phantom and production BOMs, to precisely track the components and subassemblies required for each finished good. This ensures accurate costing, efficient picking, and consistent product quality.

- Execute with Confidence on the Shop Floor: Empower your production team with clear instructions. Production Orders guide every step of the manufacturing process. With integrated Capacity Requirements Planning (CRP), you can visualize workload across work centers, prevent bottlenecks, and ensure your resources are used efficiently to meet delivery dates.

- Achieve Real-Time Cost Control and Visibility: Understand your true production costs. Business Central uses standard costing to provide a clear benchmark, tracking variances in material usage, capacity, and subcontractor costs as they occur. This allows you to identify inefficiencies, control spending, and protect your profitability on every order.

- Integrate Subcontracting and Supply Chain Seamlessly: Manage outsourced operations without missing a beat. Easily create purchase orders for subcontracting services, send components to vendors, and receive finished subassemblies back into inventory, with all costs and flows seamlessly integrated into your production and financial records.

Stop letting production complexities limit your potential. Let us show you how the powerful Manufacturing functionality within Dynamics 365 Business Central can be tailored to streamline your operations, reduce waste, and provide the end-to-end control needed to scale your manufacturing business profitably.

Key Manufacturing Functionality

- Production Orders: Manage the lifecycle of manufacturing jobs from planned to finished.

- Bill of Materials (BOM): Multi-level BOMs for defining product structures and components.

- Routings: Define the operations, work centers, and times required for production.

- Master Planning & MRP: Automated calculation of material and capacity needs.

- Capacity Requirements Planning (CRP): View load and capacity across work centers and machines.

- Standard Costing: Set and track standard costs for items and calculate production variances.

- Subcontracting: Fully manage the process of sending components to external vendors for processing.

Connect with us!

At Rekaz, we’re passionate about helping businesses grow smarter through Microsoft Dynamics 365, Cloud, and AI technologies.

Fill out the form below and our team will get back to you shortly to discuss how we can support your goals.

Phone

+966 595071832

+966 548170896

Info@rekazit.com